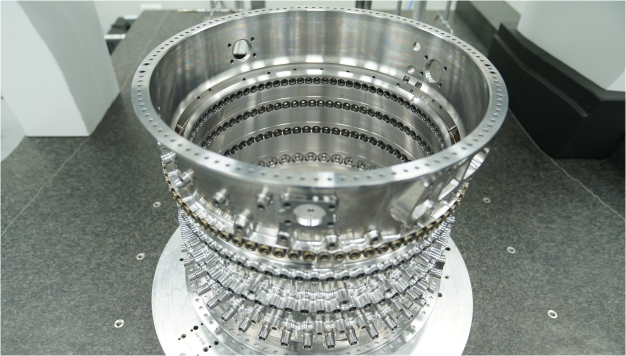

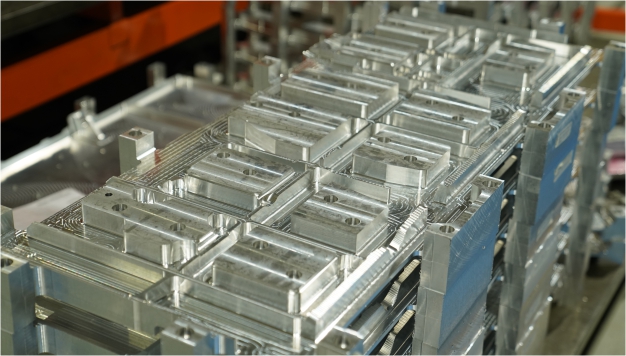

MACHINED PARTS

We have the latest high-end machines capable of machining of components up to 8 meter in Soft metal and 3 meter in Hard Metal. Tata Advanced Systems partners with technology and equipment specialists for soft metal and hard metal processing to deliver the best-in-class value through our global supply chain. Our next-gen equipment enable us to cater to a demand of over seventy thousand components each month.

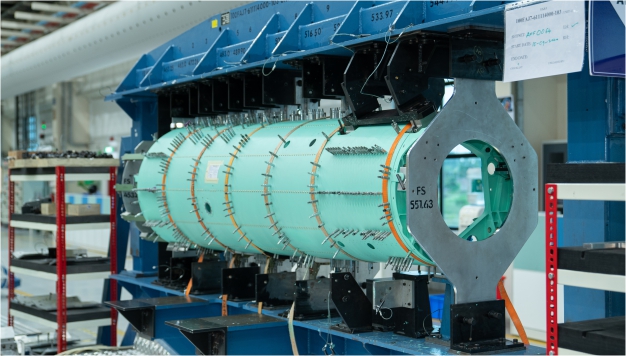

SHEET METAL FORMING

Tata Advanced Systems is the Global Single Source for the manufacturing and supply of sheet metal formed parts for some of the most advanced and widely used aircraft. The Sheet Metal Forming Facilities are equipped with best in the class tools which assists in higher production rate. In addition to extrusion stretch machines, high rate extrusion machining and nibblers, our facilities are additionally equipped with multi-axle routers and wide array of high tonnage presses up to 300 tonnes. We have also invested in the development of stretch forming capabilities.

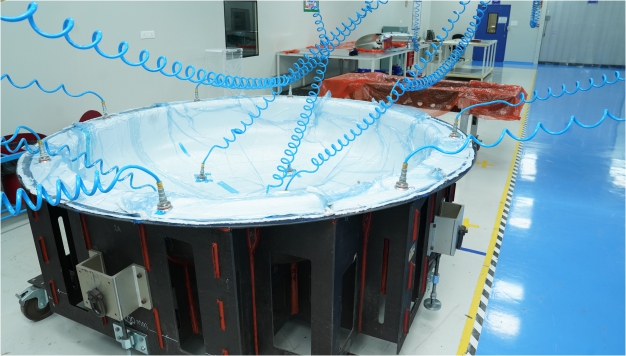

METAL BONDING

Our customer-centric approach and alignment to aircraft OEMs design and manufacturing requirements has enabled Tata Advanced Systems to establish its in-house metal-to-metal bonding capabilities which are qualified and certified by OEMs and global supply chain partners.

HEAT AND SURFACE TREATMENTS

Tata Advanced Systems takes pride in providing turnkey solutions for complete metallic detail parts manufacturing by building capacities in a wide range of heat and surface treatments such as Chemical Conversion Coating, Boric-Sulphuric Acid coating, Phosphoric Acid Anodizing, Chemical Milling and Tartaric Acid anodizing. This is in addition to our specialised areas covering primer coating and top coat painting along with test capabilities of Flourescent Penetrant Inspections, Magnetic Particle Inspection, etc. All our special processes are approved by respective customers for programs.